Handheld Laser Education & Training

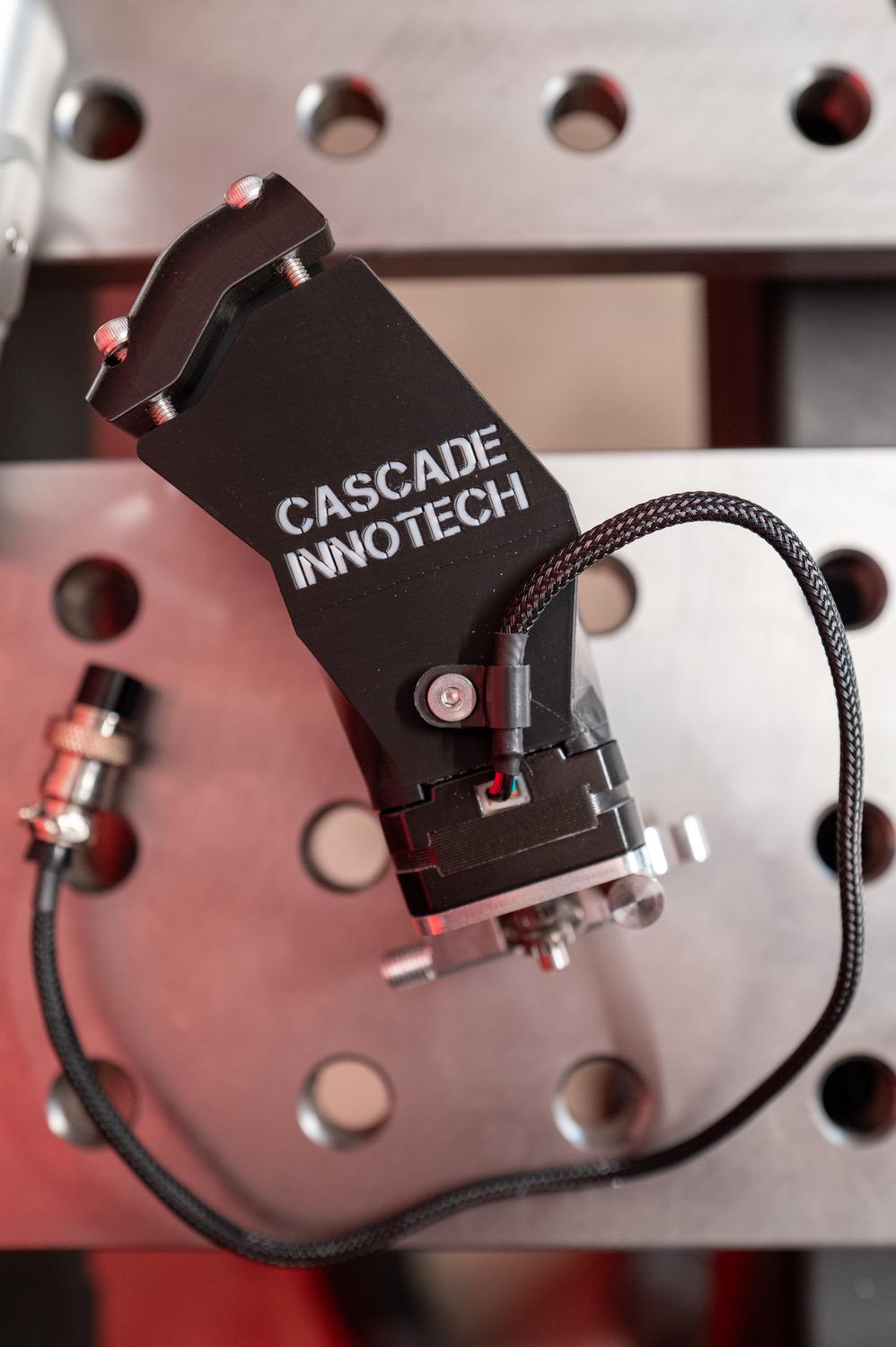

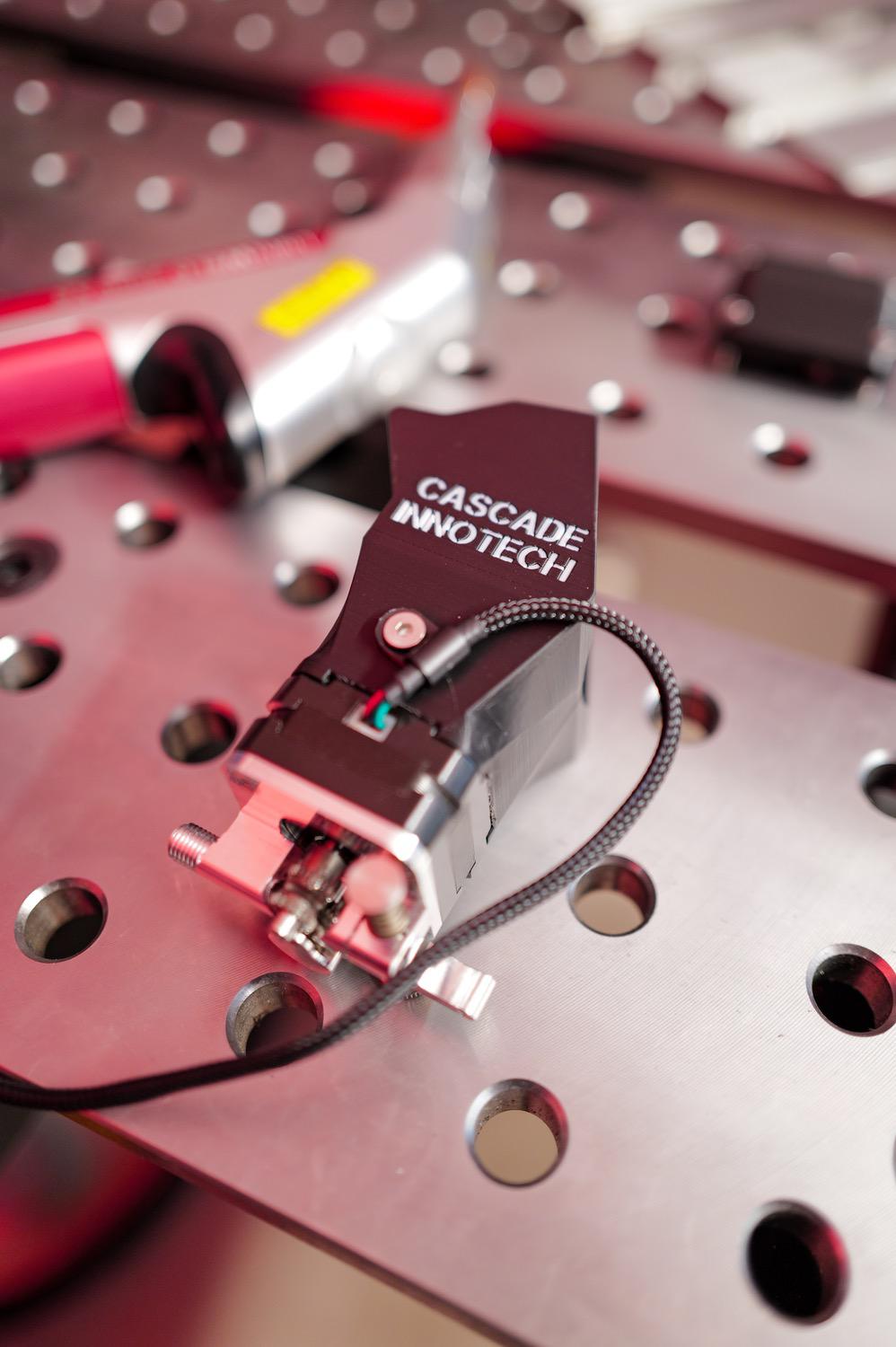

The Handheld Laser Institute was founded by Rex Alexandre in early 2024 and is focused on accelerating the industrial adoption of handheld laser welding by providing education, training, and cutting-edge research based on real-world welding applications. Engineering and educational services can be provided at our world class lab in the greater Seattle area, or directly at customer’s facilities across North America.

Resources

Latest

Stay up to date with the latest benefits news, learn tips and advice, and more! - View all

Our Services

"After purchasing our IPG Lightweld 1500 XC and spending a month playing with different projects, we called Rex and scheduled an appointment for him to come to our plant and show us exactly what our machine was capable of. He and Buddy are very knowledgeable with the laser welding process and we learned how to really fine tune this welder to get the results we wanted with mild steel, Stainless steel and aluminum. These machines have amazing capabilities and it could take years to learn what Rex can teach in a day. Highly recommended."

“Rex’s insight and guidance have been invaluable to the success of our laser welding efforts. He is extremely knowledgeable, creative, and solution focused. Whether you need technical insight, training ,or physical equipment, there is nobody better suited to making your handheld laser welding process effective.”

"There are few vendors that have the ability to support production the way HLI can. We have many varied scopes that come across our laser cell every week, and no matter what it is, Rex is always able to help provide insightful advice and technical support. No matter the material type, the knowledge and expertise from HLI helps us progress at a pace we never would have expected."

"Over the past year, I've retained Rex's services to support a number of my customers, and his expertise has been outstanding. Leveraging his prior experience training hundreds of operators and deploying handheld laser welding at scale within the world’s most advanced aerospace company, he delivered tailored, high-quality training that exceeded customer expectations across all projects. I’d highly recommend Rex’s services for any of my customers interested in accelerating their adoption of this transformational technology."

"Practical, precise, and convincing! The Handheld Laser Institute blends real shop time with hard data and structural testing that matter. Rex broke down the welding process, parameters, failure modes, and inspection techniques. He then proved performance with measurable results. Coming from a USAF Weapons Officer background but new to metalworking, I especially valued learning from an expert with SpaceX experience. The depth of knowledge and thorough documentation reinforced my confidence and confirmed I made the right call investing in my handheld laser welder and CNC combo."

Download your FREE copy of: The Effects of Critical Process Parameters on Weld Quality and Mechanical Performance in HLBW

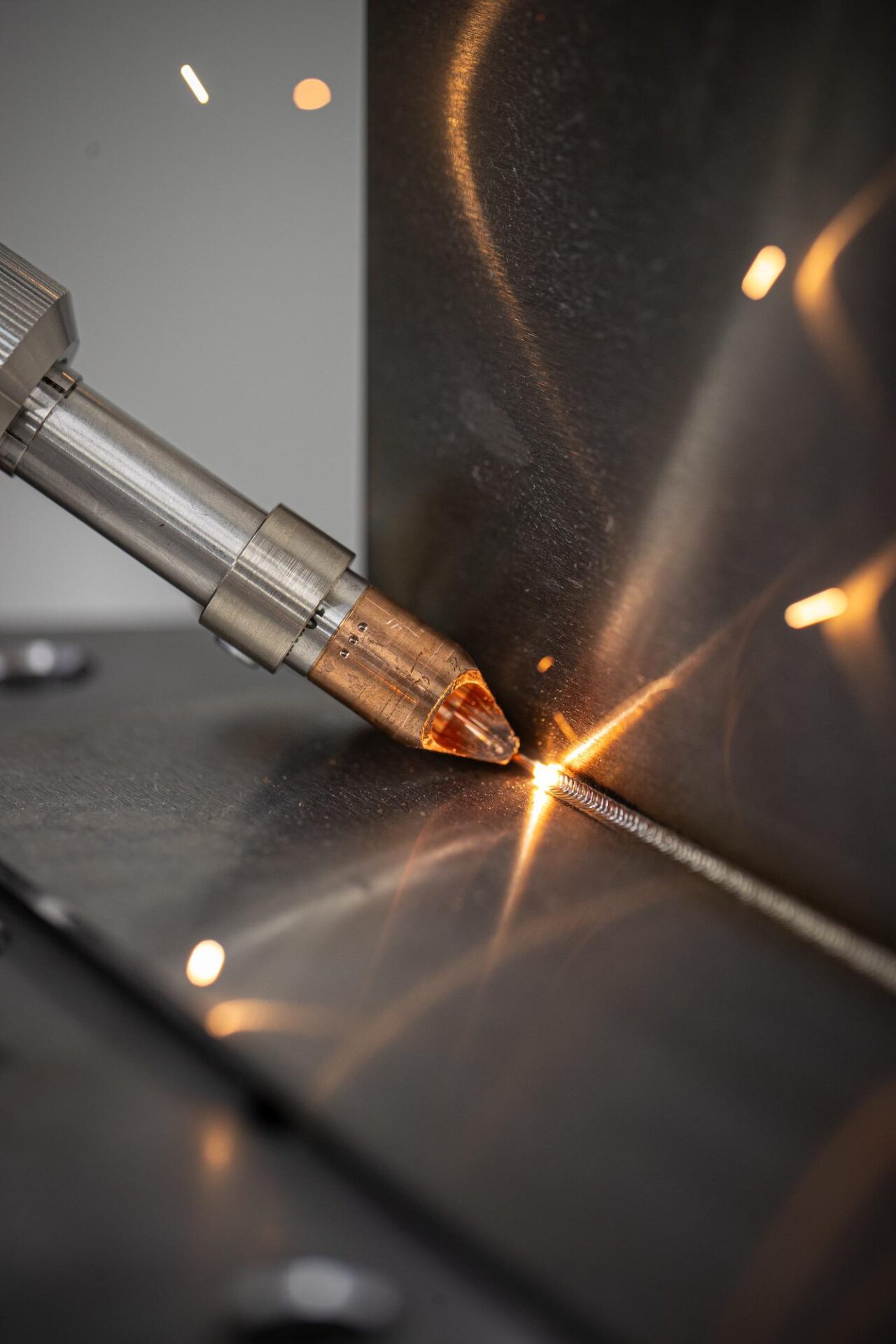

One of the most frequent comments on the internet about handheld laser welding over the past few years is something along the lines of “That weld is so cold and weak, my arc welds are so much stronger!”. Let’s dive into that a bit more…

Questions? We're here to help!